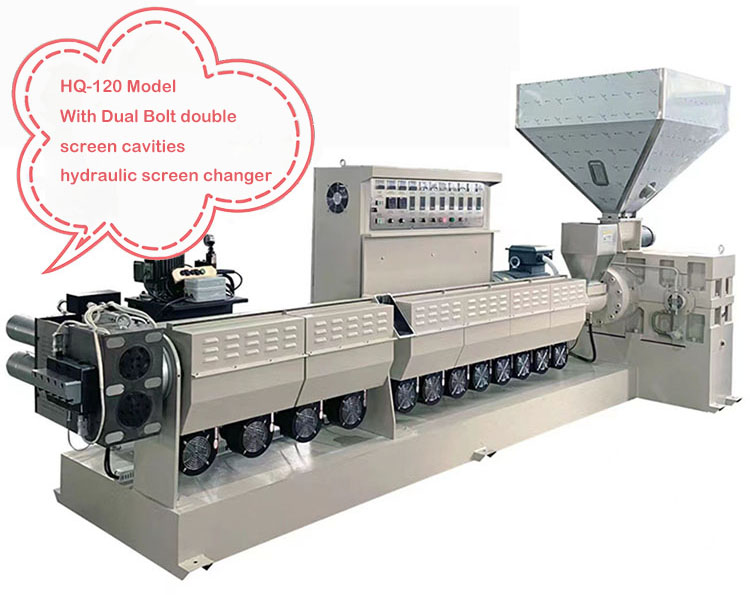

Product Name:Single Screw Extruder HQ-120 (Single-plate hydraulic screen changer)

SHQ® Single Screw Extruders combination with our other plastic recycled machine make a Plastic Granules Making Machine production line.

The essential equipment of the plastics Dana making machine production line:

Single screw Plastic Extruder 1 piece

Water cooling tank with suction motor 1 piece

Plastics Pellets Cutting Machine 1 piece

Plastics Vibrating Machine with Hopper 1 piece

Application

For materials: ABS, PC, PP, PE, PET, HIPS, TPU, PVC, etc. Coloring, mixing, modification, addition, compounding, recycling, and granulation - especially for the production of transparent PC granules.

Youtube Video: https://youtu.be/zLS5spwfgHc

Characteristic

1. Especial heating system for die head, make sure material heat quickly to the proper temperature.

2. Machine with variable frequency trimming, low power switch on, instantaneous current smooth.

3. Design and offer multiple heat treatments for screws without an extra fee.

4. Gearbox with forced cooling filtration system, reach Europe standard.

5. Screw and charging basket use special steel with heat treatment. Processing reaches the international standard.

6. Charging basket with P.L.D automatic temperature control, the material does not change color to yellow ( especially for clear polycarbonate (PC) material, and will not be born blackspot.

7. With automatic or vacuum degassing systems (Option)

8. The temperature of the die head, mesh changer, and drum are separately controlled. All drive system runs synchronously

9. Manual operation screen replacement, Single-plate hydraulic screen changer, or Dual Bolt double screen cavities hydraulic screen changer can be chosen.

Different mode of screen changer:

Manual type screen changer: more steady for the plastic quality, but need man-made working.

Single-plate hydraulic screen changer: replacement screen is easier, more simple.

Dual Bolt double screen cavities hydraulic screen changer: higher production efficiency.

Advantage

1. Power saving. Can save 30% power for a similar product in the market.

It means saving 30% on electric charges for factory owners.

2. More productive. Because our screw diameter is smaller.

3. Machine with converters, protect the whole machine. When there is a low electrical current start-up machine, it protects the gearbox and protects the screw.

4. Machine can pass the 800#, 1000# screen mesh can work on model HQ-120 Single Screw Extruder.

5. Using more wearable material for the barrel and screw. Longer life for barrels and screws

Technical Data

| Model No. | HQ-45 | HQ-65 | HQ--90 | HQ-105(High speed) | HQ-120 | HQ-150 |

Capacity (PC+ABS)

| 20-50KG/HR | 80-130KG/HR | 200-300KG/HR | 400-600KG/HR | 400-600KG/HR

| 600-1000KG/HR |

Install Dimension (mm)

| 2300*880*1500 | 3200*1000*1800

| 4500*1800*2100

| 5600*1400*1900

| 5600*2400*2500 | 6500*2800*2500 |

Total Weight

| 1500KG | 1800KG

| 2800KG

| 4800KG

| 5100KG

| 6200KG |